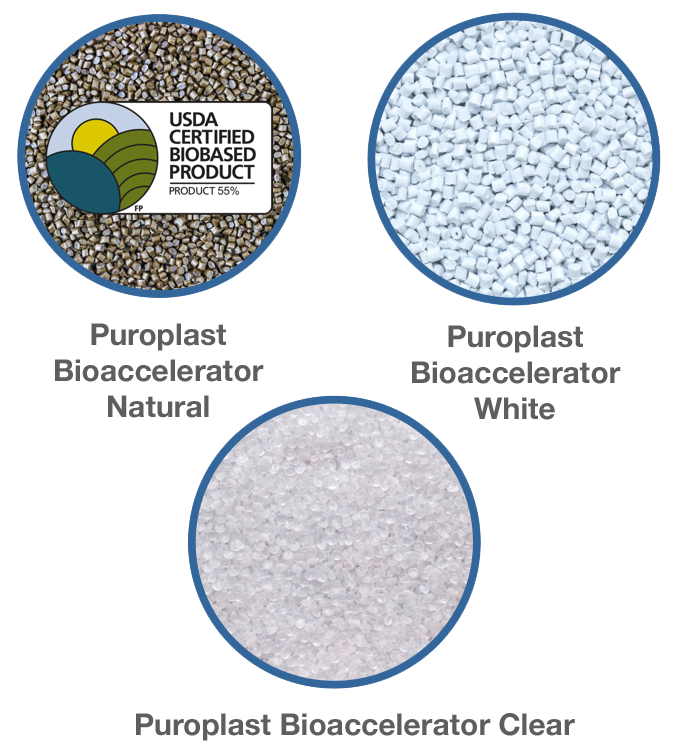

Puroplast™ Bioaccelerator Additive

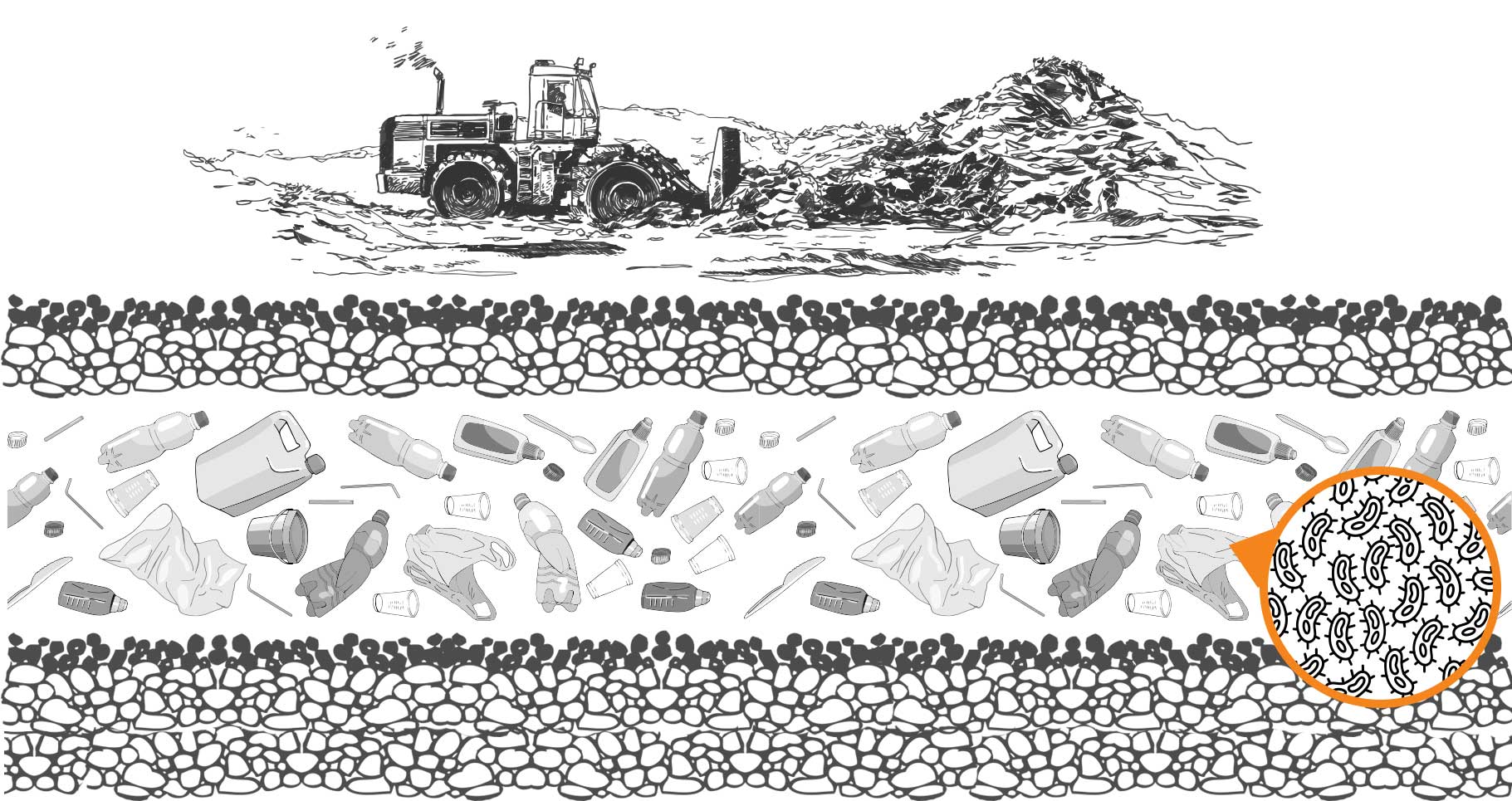

Certified additive technology that enables the bioassimilation of non-recyclable plastic products in a landfill

- Confirmed efficacy by conducting a 6-month ASTM D7475, the standard test method for determining the aerobic and anaerobic biodegradation of plastic materials under accelerated bioreactor landfill conditions.

- Customized based on intended lifespan of the product.

- Universal equipment compatibility

- Food safe, GRAS by FDA