From Seed...

to Shelf...

Agaveplast Composite Bioresins are a plant-based alternative to immediately reduce your reliance on fossil-fuel resin and reduce

the carbon footprint from a variety of HDPE, LDPE, LLDPE, PP, & TR products.

Agaveplast Composite Bioresins are a plant-based alternative to immediately reduce your reliance on fossil-fuel resin and reduce

the carbon footprint from a variety of HDPE, LDPE, LLDPE, PP, & TR products.

Reduces demand for virgin resin? YES

Reduces carbon footprint? YES

Reduces net plastic? NO

Consistent/reliable material? NO

Biorenewable? NO

USDA Biopreferred Certified NO

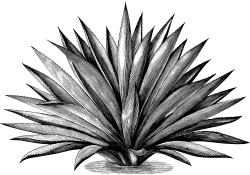

Reduces demand for virgin resin? YES

Reduces carbon footprint? YES

Reduces net plastic? YES

Consistent/reliable material? YES

Biorenewable? YES

USDA Certified Biobased? YES

*Savings estimates based on utilizing Agaveplast 75 Composite Resins. CO2 emissions reduction estimates are based on a third-party Cradle to Gate Life Cycle Assessment conducted in November 2022.

The materials in our products are GRAS (Generally Recognized As Safe) by the FDA and are safe to be used for direct and indirect food and beverage contact.

“GRAS” is an acronym for the phrase Generally Recognized As Safe. Under sections 201(s) and 409 of the Federal Food, Drug, and Cosmetic Act (the Act).

If you are interested in working with us to achieve a cleaner future, we’d love to hear from you.